We Wire Mesh The Universe

(An ISO 9001:2015 Certified Company)

Home | About Us | Industry We Serve | Certificate | Contact

WIRE MESH CONVEYOR BELT

(STAINLESS STEEL, HIGH CARBON, MILD STEEL):

What is a conveyor belt?

Conveyor Belt is an endless loop of carrying medium which consists of two or more pulleys that rotates about them. These belts are universally used in industrial settings and also in packaging, assembling units. The materials placed on the conveyor are transported from one point to other through continuous, non-stop movement. The conveyor belt is comprised of smooth metal bed or rollers on the top. If the distance is long, we suggest conveyor belt with rollers which seems to be most suitable option as it reduces friction.

There are different types of conveyor belts which are widely used in many industries:

BALANCED WEAVE TYPE BELT: This belt is mostly commonly used wire mesh conveyor belt. This belt has a smooth, flat surface of this conveyor belt which offers the best product support without marking i.e.

➥Less product marking

➥Improved tracking

➥Smoother, flatter surface

➥Increase product support

The primary purpose of the balanced belt construction is to eliminate all tendencies of the belt to creep to either side on the drive pulley. These basic features in the balanced belt construction, together with its relatively high tensile strength, make it most suitable belt for the use in the food processing industry as well as in the glass/ ceramic and metal working industries. UWP balanced weave wire mesh belt are available in Stainless Steel 304 & 316, High Carbon Steel, Low Carbon Steel etc. These belts have an easy installation process with a very low cost maintenance.

Applications of Balance Weave Wire Mesh Conveyor Belt are:

➥Heat Treatment

➥Food Industries

➥Automotive Industries

➥Glass Industries

➥Cement IndustriesCOMPOUND BALANCED WEAVE TYPE BELT: This belt comprises of extremely close and flat mesh. It is made of stainless steel and high carbon steel. This metal ensure that this type of belt long lifespan, high tensile strength, high resistant temperature, strong and durable product.

Due to the closer mesh in compound balanced weave belt there is high strength surface with high density. The belt has left and right hand spirals which are fitted closely together for a smooth, dense weave. It shows excellent results in very fine items or small products conveying as well as heavy items too. UWP’s compound balanced weave belt is extensively used in snack foods, baking products and nut/bolts.

The unique structure and the highly quality material ensures long service life. We can also provide different types of baffles at both side and centre of this belt for conveying and sorting product.

Applications for Compound Balanced Weave Wire Mesh Conveyor Belt are:

➥Particles

➥Baking Cookies

➥Biscuits

➥Nails

➥Nut & boltsDUPLEX WEAVE TYPE BELT: This belt has a woven of pairs of spirals, each pair are turned into the preceding pair, and reinforced with a rod through the hinging point. These belts are made of single directional spirals. Due to its close mesh and smooth carrying surface, the duplex belt is most efficient for carrying the small parts such as needle roller bearings and other products that would be marked by a more open mesh fabric. The design of this belt gives it low heat inertia, high strength and a good air circulation through the belt. This woven and stratified belt gives a super position of the wires and an open mesh. The edges are looped.

Applications for Duplex Weave Wire Mesh Conveyor Belt are:

➥Biscuit BakingROD REINFORCED WEAVE BELT: This belt has a high tensile strength combined with low thermal capacity is the outstanding of the belt. Also, an important characteristic of the belt is the staple-shaped reinforced rod, which not only gives great strength than single straight rod but anchors the rod within the belt structure. These belts can operate in high temperatures and the same are used in heat treatment of metal products. It allows high tension too.

Applications for Rod Reinforced Weave Wire Mesh Conveyor Belt are:

➥Wrapping machine

➥Annealing & cleaning facilities

➥Metal working industry

HONEY COMB BELT: This belt is also known as Flat wire belting, it is a straight running belt with a tremendous strength to weight ratio. It is constructed from formed flat wire strips which are connected by cross rods running through the width of the mesh. These rods are finished with either welded button edges or hooked edges. Honey Comb belt is a strong, lightweight & positively driven belt. With an large open area this belt is particularly suitable for processes such as drying, cooking, baking etc.

At UWP we demand strongly for photo, sample or drawing for honey comb belt to manufacture.

The advantages of the Honey comb belt are as below:

➥Positive sprocket drive

➥Easily cleaned

➥Open mesh construction for quick drainage

➥Flat carrying surface

➥High strength to weight ratio

➥EconomicalApplications for Honey Comb Conveyor Belt are:

➥Product Handling Systems

➥Elevating Systems

➥Cooling Systems

➥Drying Systems

➥Sorting SystemsCHAIN LINK TYPE BELT: This belt is manufactured of a series of either right or left hand spirals each turned into preceding spiral to form a continuous belt. It can be made in only one direction or made of alternating right and left hand sections. We suggest this product for applications where a belt of low initial cost is desired.

This belt is also available in rod reinforced chain link, where cross-rods are inserted across the belt width to increase the overall load capacity. This belt is mainly supplied in Stainless Steel 304 grade although we can make in other grades too on a request.

UWP offers chain link to our end users as an economic and light weight solution for low load conveying applications. Due to large open area, this belt’s design makes a popular choice for drying and cooling systems in which belt flow-through is of predominant.

Applications for Chain Link Conveyor Belt are:

➥Industrial Furnaces

➥Lift Guards

➥De-Elevating

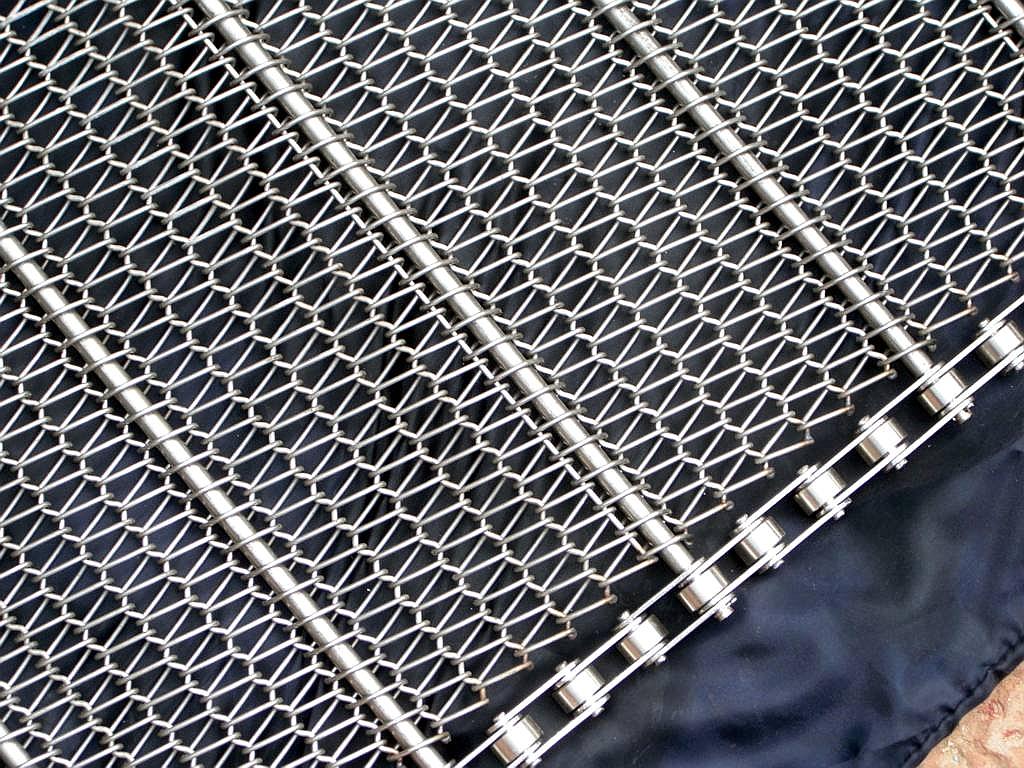

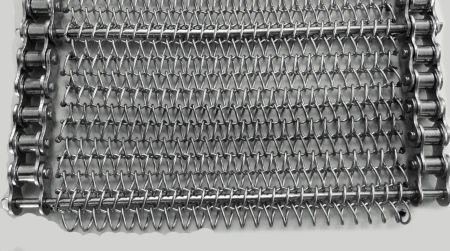

➥DrainageCHAIN DRIVEN TYPE BELT: This belt assures positive, true forward movement under the most difficult conditions. UWPs roller chain has proven to be the most popular choice for use with the various metal mesh belt constructions.

These are usually rods, pipe and tubing, bars, which are passed through or attached to the metal mesh belt and affixed to the chain by means of chain and its accessories or by acting as pins of the chain.

The advantages of the Chain driven belt are as below:

➥Because chain is driven by sprocket, meandering does not occur.

➥Various types of chain can be applied by adjusting belt pitch.

➥It’s easy to attach side guard and product stopper in combination with chain and cross rod.Applications for Chain Driven Conveyor Belt are:

➥Shrink Wrapping

➥Baking

➥Ceramics

➥Ceramics

➥Snack FoodsENROBER BELT: UWP’s enrober belt offers a large variety for light duty applications in metal working, food processing and other industries. They are made up of Stainless Steel wire of spring wire. These belts are executed with single loop which are most commonly preferred and other is double loop edges. It can develop a big range of standard dimensions and also can manufacture all the other non standard dimensions too because of its multi adjustable production machinery.

These belts can be equipped with little cams, or with special formed internal wire to the carry the product on a special way. These belts are normally driven by toothed sprockets, which are made of stainless steel or plastic. The sprockets are made to fit the belt and are adapted to the diameter as per client’s requirement.

The belt is determined by its pitch, wire diameter, the number of spaces and the dimensions of these spaces and the looped edge is determined by the wire diameter also the width of the belt is free to choose.

The advantages of the Enrober belt are as below:

➥Small transfers

➥Larger open area

➥Hygienic design with easy cleaning

➥Non slip positive drive

➥Accurate tarckingApplications for Enrober Belt are:

➥Meat Industries

➥Pizza Industries

➥Chocolate Industries

➥Nuts & fruits Industries

➥Bread Industries

Video